Improving Production Efficiency in Manufacturing

A case study on how our Lean Six Sigma program helped a manufacturing company increase their production efficiency."

Admin & Finance

- Improvement of the Production Process of Training Publications, France, Germany

- Improvement of the Legal and Commercial Framework, France

- Optimize Technical Publications Process, Germany

- Improvement of Approval Processes, Germany

- Improvement of Financial Forecasting Process, Germany

Customer Services & Sales

- Improvement of Business to Customer invoice process – Customer Services & BackOffice, Netherlands

Energy

- Reduce Works Power by Eliminating Recycle Pump overuse in a Electricity Gas Power Station, UK

- To optimize the cooling water usage a Electricity Coal Power Plant, Belgium

- Optimize the coal process in an Electricity Coal Power Plant, France

- Optimize the water consumption (from natural sources) in an Electricity Gas Power Plant, France

- Optimize biomass co-firing in an Electricity Coal Power Plant, Netherlands

ICT & Design

- Reduce costs induced by changes in harness design on Telecom Spacecrafts, France

- Mechanical design process tailoring, Germany

- Improve the process to produce a digital identity for access management, Germany

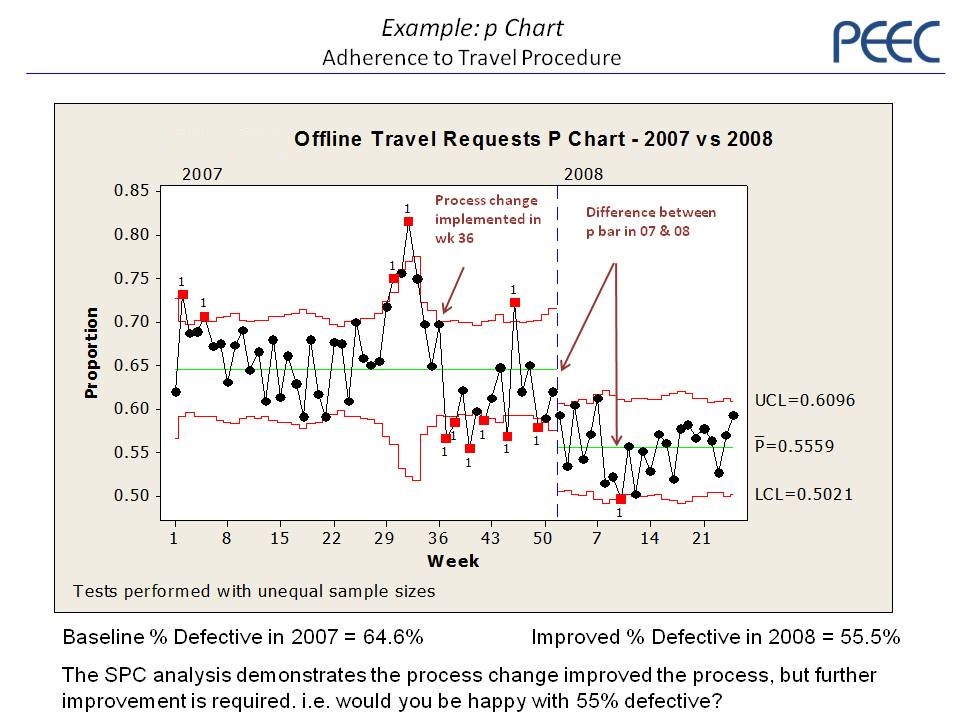

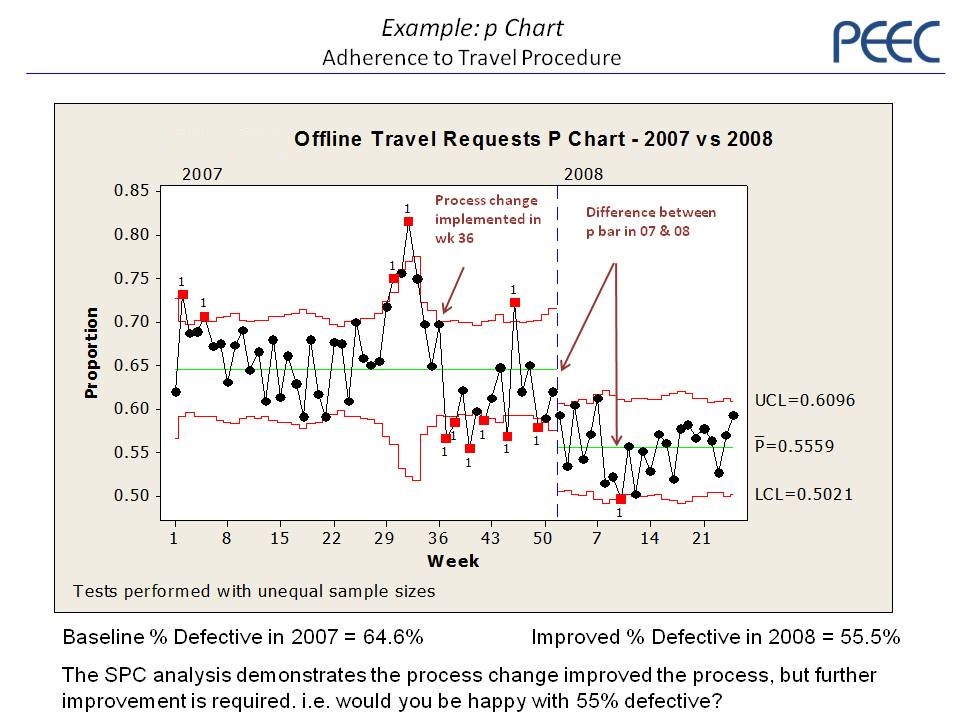

- Improvement of Travel Management Process, France

Logistics

- Reduce MGB lead time between (WIP) PC and FAL, France

- Improvement of the logistics for the FAL throughput time, Spain

Production

- Enhanced Execution & Delivery of assembled Aircrafts, France

- Lean Production Concepts in Main Blade production, Germany

- Reduction of person hours for orders manufactured on significant machines, Germany

Maintenance

- Optimisation of daily maintenance order process, Netherlands